This site uses non-intrusive cookies to enable us to provide a better user experience for our visitors. No personal information is collected or stored from these cookies. The Society's policy is fully explained here. By continuing to use this site you are agreeing to the use of cookies.

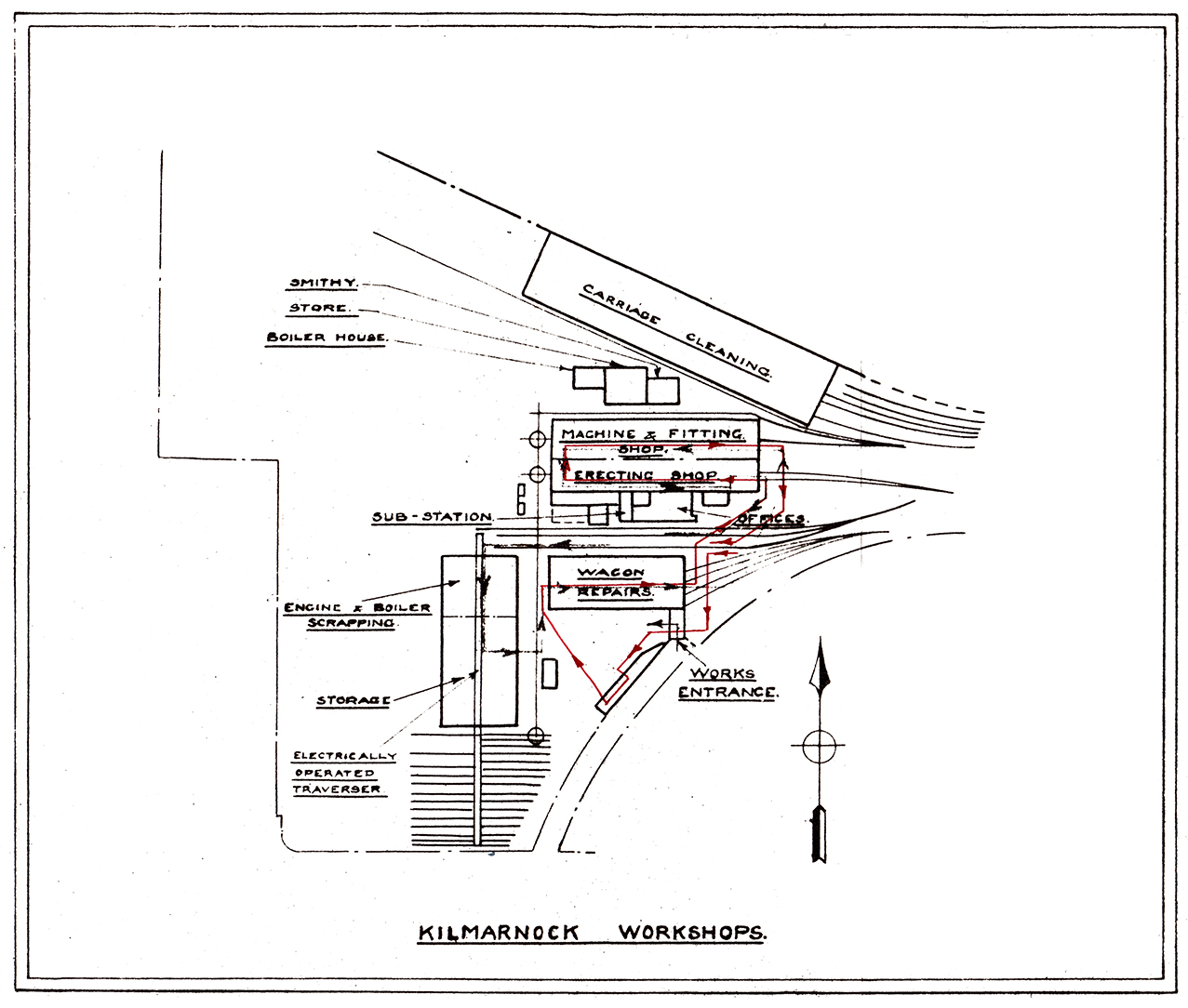

Kilmarnock Works, prior to the Amalgamation, was the Locomotive Works of the Glasgow and South Western Railway and continued to operate as a main Repair Shop until 1929. At that time it was decided to concentrate all the heavier classes of locomotive repairs for the Northern Division at St. Rollox and with the except ion of the Erecting Shop, Tender Shop, Paint Shop and Carriage Shop, the buildings were demolished and the machinery and plant where transferred elsewhere. The staff was also reduced from 700 to 97.

In July, 1942, when a general increase in output of repaired locomotives was called for, it was found necessary to extend very considerably the activities at Kilmarnock. The staff was then increased to 220 and the undernoted additional machines installed :-

Wheel lathe

Vertical boring machine

Pendulum link grinder

Milling machine

Plain grinder

Piston rod grinder

Hydraulic press - hand operated.

This Shop consists of two bays, one of which is used as a Machine Shop, being equipped with suitable plant for dealing with tyre turning, axleboxes, motion details, etc.

Repairs to cranes for Operating and Goods Departnents are also carried out in this bay, which is served by a 10-ton overhead electric travelling crane.

The other bay, which has two 35-ton overhead electric cranes, is used for locomotive and tender repairs. The engines are taken by crane to the Stripping Section, which is adjacent to the degreasing bosh tanks, and then to the repair pits. After repair the weights are checked on a four-table locomotive weighing machine situated inside the entrance to the Shop.

The Shop is supplied with compressed air and acetylene and is also wired for electric welding.

In this Shop, which is fed by a 20-ft. traverser, the cutting up of obsolete engines, boilers and tenders is carried out. Oxy-acetylene blow pipes are used and there is also a shearing machine for cutting scrap plates into suitable sizes for sale.

A 10-ton overhead electric crane serves one of the two bays.

A portion of the Shop is let to Messrs. John Walker and Sons Ltd. as an Empty Bottle store, whilst a further area is utilised for the storage of machine tools for the Ministry of Supply. SMITHY

The Smithy is equipped with a 5-cwt. steam hammer and deals withall the lighter Smith work required for locomotives and wagons, also crane repairs, Any heavier work is sent to St.Rollox.

Repairs to copper pipes are carried out in this Shop, a brazing hearth being provided for this purpose.

This Shop, which was the engine Paint Shop prior to 1931, carries out Light repairs to wagons at the rate of 280 per week. It is equiped with a circular saw.

This was formerly a Carriage Repair Shop and since 1928 has been used as a Carriage Storage and cleaning shed.

Electric current is supplied by the Ayrshire Electricity Board at 11,000 volts to Works sub-station, where it is transformed to 420 volts A.C. for power and 230 volts A.C. for lighting. It is also converted to 230 volts D.C. by a Mercury rectifier for machines with D.C. motors.

Compressed air. The Air Compressor is of 220 cu. ft. capacity.

Steam. A locomotive boiler situated adjacent to the Smithy supplies steam for the steam power and heating the Shops.

The Canteen was opened on the 9th April, 1945, and was converted from an old disused office. It is fully equipped as a modern canteen and main mid-day meals can be served to the number of 66 at one time.

This Canteen serves mainly the Workshops but it is open to employees of other Departments in the district.

| Section | Total No |

|---|---|

| Locomotive | 233 |

| Wagon | 27 |

| Carriage cleaning | 29 |

| 233289 |

The average weekly output of Locomotive repairs is :-

| Heavy | 1.0 |

| Light | 3.0 |

| Running | 0.5 |

| Total | 4.5 |

Site contents Copyright © LMS Society, 2026

February 18th, 2026

Site contents Copyright © LMS Society, 2026